Production Guide

The packaging itself is the product.

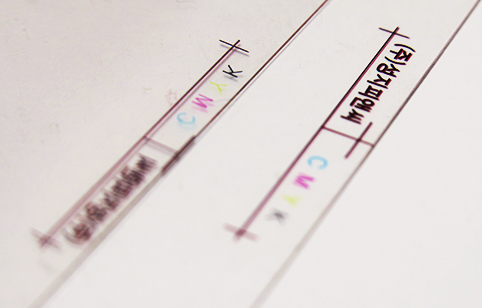

Fabric Type

-

Type of Fabric

The most important first step is to choose the origin according to the various products (EX, cosmetics, electronics, food, gifts, etc.).

You can choose the color you want and reasonable price by choosing the right paper for your application and the person you are using.

SC

Recycled pulp (high paper) as the main material produced by the product color may appear dull when working. Only one side of Manila can be used as the print side, and the back side is gray. Cheapest price and mainly used in industrial products boxes (confectionery, pharmaceuticals, etc.) and agricultural products boxes.Weight 180, 240, 260, 280, 300, 350, 400, 450, 500 (Unit : g/m²)

IV

Made from recycled pulp (highland paper) as the main material, both sides are made of white pulp. It has superior printing aptitude and high strength, and both sides are made of white pulp. However, the inner center section is grayish because it contains recycled pulp.Weight 240, 280, 300, 350, 400, 450, 500 (Unit : g/m²)

RIV

None fluorescence product uses 100% natural pulp and has excellent printability, high strength, and a luxurious surface. The fabric is made of only white pulp from the front, back and inside of the fabric. The back is a little ivory color and has durable durability. It is mainly used in food packaging containers and advanced general packaging materials and often used as a back print to make the product feel matte.Weight 230, 260, 280, 300, 350, 400, 450 (Unit : g/m²)

CCP

The premium packaging material which surface has high gloss and high smoothness, excellent strength and acceptability, which makes the appearance of the package stand out. The front, back and inside of the fabric are made of white pulp and the back of the fabric is also white. The front part has a shiny coating and is used in many cosmetics and medicines.Weight 250, 300, 350, 400 (Unit : g/m²)

Special Paper

Used for high-end printing and wrapping paper, and has imported paper and special paper with various textures and patterns. Mainly used for fine cosmetics and red ginseng products.

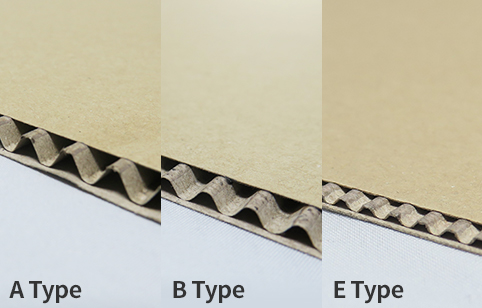

Corrugated Paper

Usage differs according to the thickness of the corrugated type, and used when there are various types of corrugate. Mainly concerned about the damage of heavy products and products. The thicker the thickness of the corrugate, the higher the buffering effect, but the weight of the case itself becomes heavy.- A Corrugated Type

Thickness 4.5~4.8mm - E Corrugated Type

Thickness 1.2~1.4mm - B Corrugated Type

Thickness 2.5~3.0mm